GOODS-TO-PERSON

Goods to person is a solution that use a self-guided vehicle AMR to transport materials, goods, or products in a manufacturing or warehouse. It can be programmed to perform a variety of tasks, such as transporting materials between different locations within a warehouse, picking up and delivering products to assembly lines, or moving finished goods to a shipping area, loading and unloading materials from conveyor systems.

Some of the advantages of solution:

- Increased Efficiency: AMRs can operate 24/7 and can be programmed to perform tasks faster than human operators. This can lead to increased productivity and throughput.

- Improved Safety: AMRs are designed with safety in mind and are equipped with sensors that can detect obstacles and stop the vehicle to prevent collisions. This can reduce the risk of accidents and injuries in the workplace

- Reduced Labor Costs: By using AMRs, companies can reduce the need for human operators, which can lead to cost savings over time.

- Digitalize the inventory information and track the whole process

- Intelligent Maintenance: The robot control system regularly sends notifications of maintenance information and reminds the staff to do regular maintenance on the AMRs, which is easy and convenient.

Good to person can be applied in variety scenarios

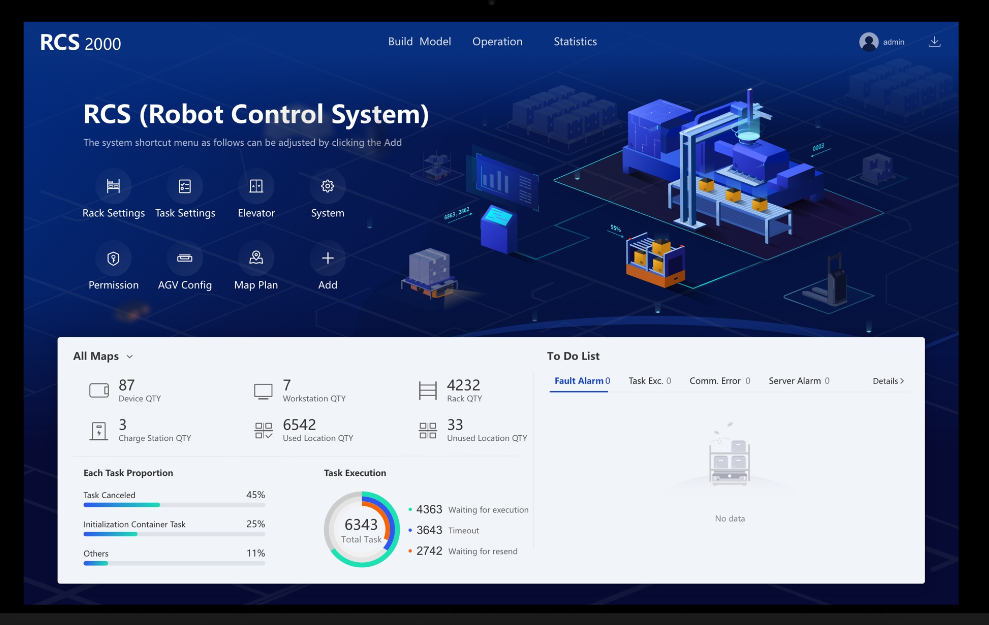

The core of Hikrobot software platform architecture is the Intelligent Warehouse Management System and the Robotic Control System. iWMS with the upper-level system seamlessly to realize intelligent warehouse management at high efficiency and low costs. RCS is used to build the map model and dispatch various robots. The two systems work together to link through the whole logistics process, connect various transfer scenarios seamlessly.