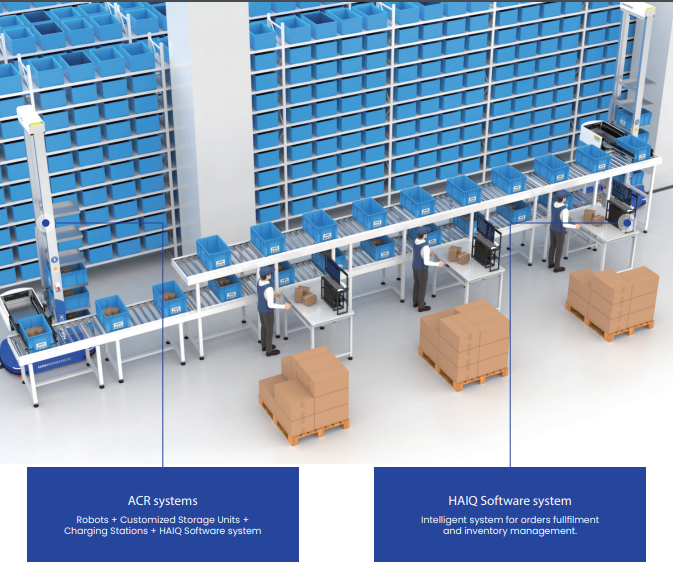

WAREHOUSE AUTOMATION WITH ACR SYSTEMS

The ACRs are automated storage and retrieval systems designed and developed specifically to handle cases. They include proprietary HAIPICK robots and intelligent software system HAIQ. The HAIPICK robots do the picking, sorting, and transport between shelves and workstations. HAIQ system is the central command for HAIPICK robots, conveyor belts, loading and unloading workstations and other devices including robotic arms, AGVs or AMRs made by others.

Key benefits from systems:

- Optimize warehouse space: The customizable storage solution can maximize the use of the existing space, increase the storage capacity per unit area and lower the cost of land use, with up to 95% of the vertical space put in use and the storage density increased by 80% – 400%.

- Increase accurate and efficient: Powered by AI algorithms, the ACR systems boosts totes picking accuracy to 99.99%, improving accuracy and efficiency of order fulfillment.

- Reduce labor cost by improving employees’ efficiency by 3-4 times.

- Flexible solution allows easy expansion of business: As e-commerce booms, some 3PL companies see capacity of their original facilities reaching a limit. With ACR systems, the expansion of warehouse can be realized flexibly and agilely. In terms of compatibility, the combination of the robots, the HAIQ system can ensure the flow of information between multiple devices. Users can deploy ACR systems easily according to their changing business needs, without causing disruptions to operation.

Currently, 3PL, e-commerce, apparel, retail, grocery, automotive & manufacturing, electronics, and pharmaceutical industries are already turning to ACR to enhance and accelerate their operations.

ACR solutions are helping warehousing, distribution centers, and manufacturing facilities worldwide in over 30 countries advance their operations. Below are some reference: